PRODUCT DESCRIPTION

Product Code: Single Analyte Custom Grade Solution

Catalog Number: CGTA1

Lot Number: P2-TA680046

Matrix: tr. HNO3

tr. HF

Value / Analyte(s): 1 000 µg/mL ea:

Tantalum

Starting Material: Ta metal

Starting Material Lot#: 1818

Starting Material Purity: 99.9903%

CERTIFIED VALUES AND UNCERTAINTIES

Certified Value: 1002 ± 5 µg/mL

Density: 1.003 g/mL (measured at 20 ± 4 ºC)

Assay Information:

Assay Method #1 1006 ± 5 µg/mL

ICP Assay NIST SRM 3155 Lot Number: 110715

Assay Method #2 999 ± 4 µg/mL

Calculated NIST SRM Lot Number: See Sec. 4.2

TRACEABILITY TO NIST

-This product is traceable to NIST via an unbroken chain of comparisons. The uncertainties for each certified value are reported, taking into account the SRM/RM uncertainty error and the measurement, weighing and volume dilution errors. In rare cases where no NIST SRM/RM are available, the term 'in-house std.' is specified.

1.Thermometer Calibration

-All thermometers are NIST traceable through thermometers that are calibrated by an accredited calibration laboratory.

2.Balance Calibration

-All analytical balances are calibrated by an accredited calibration laboratory and procedure. The weights used for testing are annually compared to master weights and are traceable to NIST.

3.Glassware Calibration

-An in-house procedure is used to calibrate all Class A glassware used in the manufacturing and quality control of CRM/RMs.

TRACE METALLIC IMPURITIES (TMI ) DETERMINED BY ICP-MS AND ICP-OES (µg/mL)

CRM/RMs are tested for trace metallic impurities by Axial ICP-OES and ICP-MS. The result from the most sensitive method for each element, is reported below. Solutions tested by ICP-MS were analyzed in an ULPA-Filtered Clean Room. An ULPA-Filter is 99.9985% efficient for the removal of particles down to 0.3 µm.

|

M

|

Ag

|

<

|

0.001193

|

M

|

Eu

|

<

|

0.000198

|

M

|

Na

|

|

0.008196

|

M

|

Se

|

<

|

0.006564

|

M Zn < 0.016310

|

|

M

|

Al

|

|

0.001899

|

M

|

Fe

|

|

0.009157

|

M

|

Nb

|

|

0.001701

|

i

|

Si

|

<

|

|

M Zr < 0.011537

|

|

M

|

As

|

|

0.018215

|

M

|

Ga

|

<

|

0.000198

|

M

|

Nd

|

<

|

0.000198

|

M

|

Sm

|

<

|

0.000198

|

|

|

i

|

Au

|

<

|

|

M

|

Gd

|

<

|

0.000198

|

M

|

Ni

|

|

0.013785

|

M

|

Sn

|

|

0.000176

|

|

|

M

|

B

|

<

|

0.007956

|

M

|

Ge

|

<

|

0.000397

|

M

|

Os

|

<

|

0.000199

|

M

|

Sr

|

<

|

0.000795

|

|

|

M

|

Ba

|

<

|

0.001989

|

M

|

Hf

|

<

|

0.000795

|

n

|

P

|

<

|

|

s

|

Ta

|

<

|

|

|

|

M

|

Be

|

<

|

0.001591

|

M

|

Hg

|

<

|

0.005778

|

M

|

Pb

|

|

0.000154

|

M

|

Tb

|

<

|

0.000198

|

|

|

M

|

Bi

|

<

|

0.004773

|

M

|

Ho

|

<

|

0.000198

|

M

|

Pd

|

<

|

0.000198

|

M

|

Te

|

<

|

0.002784

|

|

|

O

|

Ca

|

|

0.001650

|

M

|

In

|

<

|

0.000198

|

M

|

Pr

|

<

|

0.000198

|

M

|

Th

|

<

|

0.001989

|

|

|

M

|

Cd

|

<

|

0.000198

|

M

|

Ir

|

<

|

0.000597

|

M

|

Pt

|

<

|

0.066437

|

M

|

Ti

|

<

|

0.019095

|

|

|

M

|

Ce

|

<

|

0.000198

|

O

|

K

|

|

0.036885

|

M

|

Rb

|

<

|

0.000198

|

M

|

Tl

|

<

|

0.000198

|

|

|

M

|

Co

|

|

0.000121

|

M

|

La

|

<

|

0.000198

|

M

|

Re

|

<

|

0.000198

|

M

|

Tm

|

<

|

0.000198

|

|

|

M

|

Cr

|

|

0.004904

|

M

|

Li

|

<

|

0.004773

|

M

|

Rh

|

<

|

0.000198

|

M

|

U

|

<

|

0.000795

|

|

|

M

|

Cs

|

|

0.000110

|

M

|

Lu

|

<

|

0.000198

|

M

|

Ru

|

<

|

0.000199

|

M

|

V

|

<

|

0.000795

|

|

|

M

|

Cu

|

|

0.000949

|

O

|

Mg

|

|

0.004127

|

i

|

S

|

<

|

|

M

|

W

|

<

|

0.011139

|

|

|

M

|

Dy

|

<

|

0.000198

|

M

|

Mn

|

|

0.001159

|

M

|

Sb

|

|

0.002275

|

M

|

Y

|

<

|

0.000397

|

|

|

M

|

Er

|

<

|

0.000198

|

M

|

Mo

|

|

0.001866

|

M

|

Sc

|

<

|

0.030632

|

M

|

Yb

|

<

|

0.000198

|

|

|

INTENDED USE

- For the calibration of analytical instruments and validation of analytical methods as appropriate.

INSTRUCTIONS FOR THE CORRECT USE OF THIS REFERENCE MATERIAL

1.Storage and Handling Recommendations

-Store between approximately 4° - 30° C while in sealed TCT bag.

-While stored in the sealed TCT bag, transpiration of this CRM/RM is negligible. After opening the sealed TCT bag transpiration of the CRM/RM will occur, resulting in a gradual increase in the analyte concentration(s). It is the responsibility of the user to account for this effect. When the bottle is weighed both before and after being placed in storage, the mass difference observed will be a measure of transpiration mass loss.

-After opening the sealed TCT bag, keep cap tightly sealed when not in use and store between 4° - 24° C to minimize the effects of transpiration. Use at 20° ± 4° C to minimize volumetric dilution error when using the reported density. Do not pipette from the container. Do not return removed aliquots to container.

Atomic Weight; Valence; Coordination Number; Chemical Form in Solution - 180.95 +5 6,7,8 TaOF6-3

Chemical Compatibility - Soluble in concentrated HCl and dilute HF / HNO3. Avoid neutral to basic media. Unstable at ppm levels with metals that would pull F- away. (i.e. Do not mix with Alkaline or Rare Earths or high levels of transition elements unless they are fluorinated) Stable with most inorganic anions provided it is in the chemical form shown above.

Stability - 2-100 ppb levels stable (alone or mixed with all other metals that are at comparable levels) as the TaOF6-3, for 2 months {2-10 ppb} in 1% HNO3 / LDPE container and for 5 months at the 100 ppb level under same conditions. 1-10,000 ppm single element solutions as the TaOF6-3 are chemically stable for years in 2 - 5% HNO3 / trace HF in an LDPE container.

Ta Containing Samples (Preparation and Solution) -Metal (Soluble in HF / HNO3); Oxide - Very resistant to al acids including HF (fusion with K2S2O7,, KOH, or Na2CO3) ; Organic Matrices (dry ash at 450 EC in Pt0 and dissolve by fusing with Na2CO3 or K2S2O7)

Atomic Spectroscopic Information (ICP-OES D.L.s are given as radial/axial view):

Technique/Line EstimatedD.L. Order Interferences (underlined indicates severe)

ICP-MS 181 amu 2 ppt N/A 165Ho16O

ICP-OES 226.230 nm 0.03 / 0.01 µg/mL 1 Sb, Nb

ICP-OES 240.063 nm 0.03 / 0.004 µg/mL 1 Hf, Fe, Bi

ICP-OES 268.517 nm 0.03 / 0.005 µg/mL 1 Cr, Ru, HF, W

HF Note: This standard should not be prepared or stored in glass.

HAZARDOUS INFORMATION

-Please refer to the Safety Data Sheet for information regarding this CRM/RM.

HOMOGENEITY

-This solution was mixed according to an in-house procedure and is guaranteed to be homogeneous. Homogeneity data indicate that the end user should take a minimum sample size of 0.2 mL to assure homogeneity.

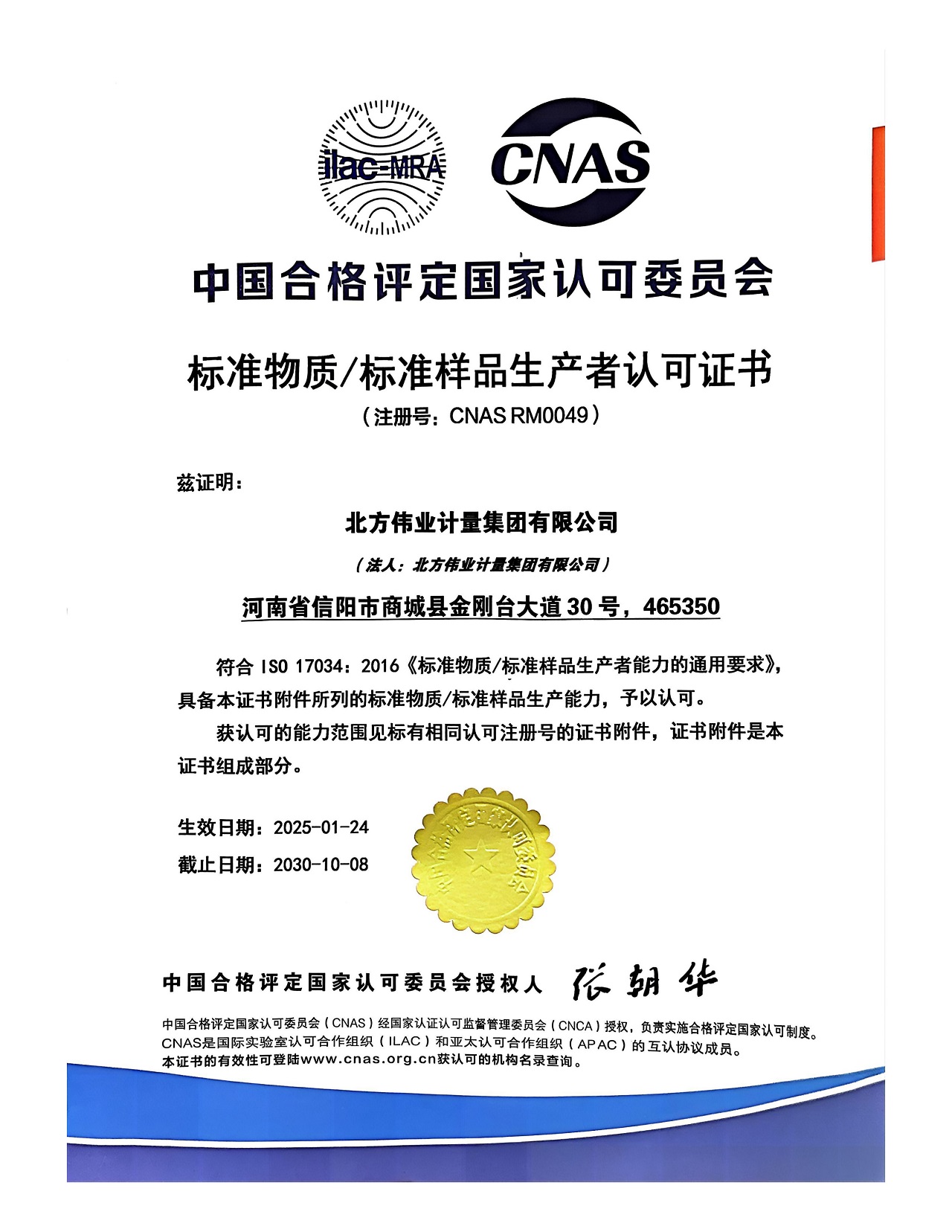

QUALITY STANDARD DOCUMENTATION

1.ISO 9001 Quality Management System Registration

- QSR Certificate Number QSR-1034

2.ISO/IEC 17025 "General Requirements for the Competence of Testing and Calibration Laboratories"

- Chemical Testing - Accredited / A2LA Certificate Number 883.01

3.ISO 17034 "General Requirements for the Competence of Reference Material Producers"

- Reference Material Producer - Accredited / A2LA Certificate Number 883.02

CERTIFICATION, LOT EXPIRATION AND PERIOD OF VALIDITY

注:以上信息仅供参考,以产品附带证书为准。